NFPA 2112, the Standard on Flame-Resistant Clothing for Protection of Industrial Personnel against Short-Duration Thermal Exposures from Fire, outlines minimum performance requirements for garments designed to protect workers from flash fire hazards. One of the critical parameters in this standard is Heat Transfer Performance (HTP). HTP measures the ability of flame-resistant fabrics to resist heat transfer during thermal exposure, simulating both contact and spaced conditions. It is evaluated according to ASTM F2700.

HTP is expressed in calories per square centimetre (Cal/cm²). The higher the number, the better the fabric’s thermal insulation.

- Why HTP Was Introduced?

- In the 1980s, TPP was used for testing firefighter gear.

- But by the 2000s, scientists realized something important:

TPP was actually showing how much energy caused burns, not how well fabric blocks heat.

So, to fix this, they introduced a new test called HTP.

HTP (Heat Transfer Performance):

- What it does: HTP only measures how fast or how much heat passes through the fabric, it doesn’t say if a person gets burned or not.

- It’s focused on heat transfer, not burn prediction.

Simply put, HTP indicates the time before a second-degree burn begins to develop. In essence, it provides a clear warning about how much time the wearer has to escape a hazardous thermal situation. For instance, if a fabric has an HTP value of 10 Cal/cm², it means that second-degree burns may begin after 5 seconds of heat exposure.

A higher HTP rating indicates better insulation and more protection, effectively buying the wearer precious seconds to react, escape, or minimize injury. In life-threatening flash fire situations, those extra seconds can mean the difference between safety and serious harm. Higher the HTP value, the longer it takes for heat to penetrate the fabric and damage the skin.

Scientific Way – HTP

It is a more scientific way to measure the fabric’s thermal insulation.

- How is HTP Measured?

It quantifies a fabric’s ability to resist heat transfer from a flash fire-like thermal exposure. The goal is to determine how much thermal energy (in Cal/cm²) a fabric can withstand before causing second-degree burns. It measures the rate at which heat penetrates a fabric from a continuous and controlled thermal source.

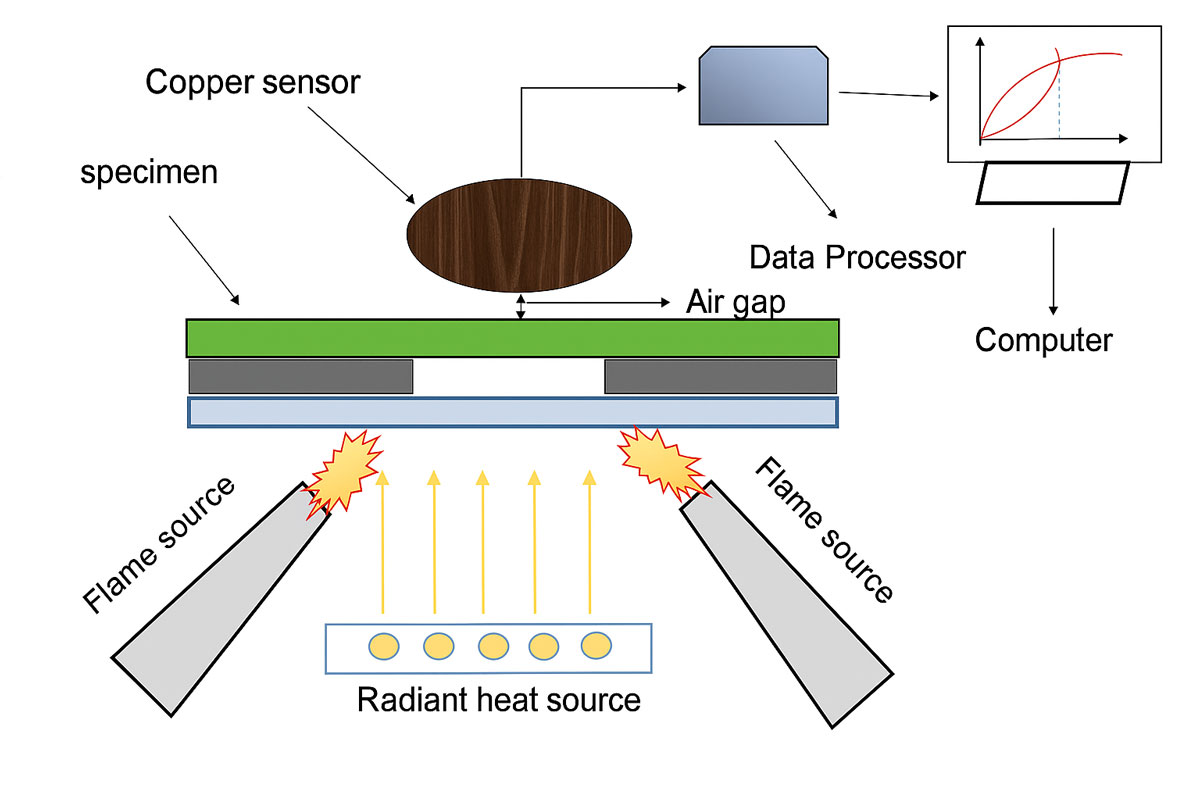

The standard test method used is: ASTM F2700 – Standard Test Method for Unsteady-State Heat Transfer Evaluation of Flame Resistant Materials for Clothing When Exposed to a Combined Convective and Radiant Heat Source.

A sample of the fabric is exposed to combined radiant and convective heat. The heat flux is maintained at 2 Cal/cm²/sec. Sensors behind the fabric measure the time it takes for enough energy to pass through and potentially cause a second-degree burn.

HTP Rating Formula:

HTP (Cal/cm²) = Heat Flux (Cal/cm²/sec) × Time to Burn (seconds)

What Does NFPA 2112 Require in HTP?

The NFPA 2112 standard specifies a minimum Heat Transfer Performance (HTP) rating of 6.0 Cal/cm² when tested in a spaced configuration (referred to as spaced Heat Transfer Performance or spaced HTP) and 3.0 Cal/cm² in a contact configuration (known as contact HTP).

Spaced HTP which simulates an air gap between the garment and the skin (like what naturally occurs when a garment fits loosely). The fabric is suspended 6 mm above the sensor during test.

Contact HTP simulates tight-fitting garments or instances where the garment is compressed against the skin (e.g., due to seatbelts, kneeling, or pressure from tools). The fabric is placed directly on top of the sensor. Since there is no insulating air gap, heat transfers faster and burn risk is higher.

Tarasafe Fabrics Meet and Exceed NFPA 2112 TPP Standards

When it comes to industrial safety, especially in environments prone to convective and radiant heat hazard, thermal protection is non-negotiable. That’s why the HTP (Heat Transfer Performance) rating of flame-resistant (FR) fabrics is a critical benchmark. Tarasafe International Private Limited, a trusted name in protective clothing, ensures that all of its FR fabrics are engineered to meet or exceed the HTP requirements set by NFPA 2112.

Tarasafe has rigorously tested and evaluated its flame-resistant fabrics under both contact and spaced exposure configurations, with certifications obtained from a UL-accredited laboratory. Our fabrics i.e. TARAMID VA180U, Taraknits MACINCO250IL, Taracomfort CNA240ST-E, Taramod MACINCO 200 comfortably pass the minimum spaced HTP of 6.0 Cal/cm² and contact HTP of 3.0 Cal/cm², demonstrating their ability to perform under both loose-fit and compression scenarios, whether it’s a free-hanging sleeve or a tightly strapped area like the waist or elbows.

Conclusion – HTP

When lives are at stake, every second counts. Heat Transfer Performance (HTP) is not just a test result- it’s a critical measure of safety. Whether you’re a safety officer sourcing FR garments, or a worker operating in high-risk zones, understanding and prioritizing HTP can make all the difference. Always choose certified garments that meet or exceed NFPA 2112 standards, and look beyond just comfort and price- performance saves lives.

Leave a Reply