In industries handling flammable gases, vapours, liquids, or combustible dust, ensuring workplace safety begins with understanding hazardous area classifications. These classifications provide a structured way to assess risk, select the right equipment, and comply with international safety standards. Let’s explore how zones are defined, the standards that govern them, and what businesses need to consider for compliance – Know Your Zone.

Why Hazardous Area Classifications Matter

Explosive atmospheres pose risks to personnel, equipment, and the environment. Classifying zones helps mitigate these risks by defining the probability and duration of hazardous presence. It guides the choice of intrinsically safe equipment, ensures regulatory compliance, and minimizes the chances of ignition or catastrophic incidents.

Gas and Dust Zone Classifications

Hazardous areas are broadly divided into gas and dust categories:

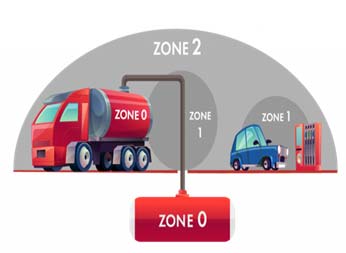

Gas Zones – Know Your Zone

- Zone 0: Explosive atmosphere is present continuously or for long periods (>1000 hours/year)

- Zone 1: Likely to occur during normal operations (10–1000 hours/year)

- Zone 2: Rarely present, and only for short durations (<10 hours/year)

Dust Zones – Know Your Zone

- Zone 20: Combustible dust is present continuously or frequently

- Zone 21: Likely during abnormal operations

- Zone 22: Rare and short-lived dust accumulations

Each zone has distinct equipment and safety requirements. For example, Zone 0 allows only intrinsically safe, non-sparking, and ATEX/IECEx-certified devices, while Zones 1 and 2 permit broader but still controlled use of certified equipment.

Zone 0: The Highest-Risk Environment

Zone 0 demands the strictest controls because explosive atmospheres are continuously present. Typical industries include refineries, chemical plants, fuel storage facilities, and pharmaceutical labs. Prohibited items include standard steel tools, ordinary mobile phones, unapproved batteries, and friction-prone plastics. Only certified intrinsically safe equipment, conductive materials to prevent static build-up, and encapsulated electronics are permitted.

Examples of industries or environments where zone 0 may be present

Petrochemical refineries: Certain areas within refineries, such as storage tanks, process vessels, or pipelines where highly flammable substances are handled, can fall under zone 0 classification.

Chemical manufacturing facilities: Specific processing units or storage areas dealing with volatile chemicals or solvents may be designated as zone 0.

Fuel storage and distribution: Underground storage tanks, fuel depots, or loading areas where flammable fuels are present can be classified as zone 0.

Pharmaceutical laboratories: Laboratories that handle and store highly flammable or volatile substances might fall under zone 0 classification.

Global Standards and Regulations

Several international frameworks define safety in hazardous areas:

- IECEx: UN-endorsed system for global certification of equipment in explosive atmospheres.

- ATEX (Europe): Covers both workplace classification (ATEX 137) and equipment certification (ATEX 95). It ensures uniform safety standards across the EU.

- NEC (North America): Published by NFPA, widely adopted in the U.S. for hazardous electrical installations.

- CSA (Canada), EAC Ex (Russia/CIS), and INMETRO (Brazil) also provide region-specific certifications.

Despite regional variations, these standards share a common goal to safeguard workers and facilities by minimizing ignition risks.

Steps for ATEX Zone 0 Product Certification

- Understand relevant ATEX directives.

- Identify the applicable protection concept (intrinsic safety, explosion-proofing, etc.).

- Design and develop according to EN/IEC 60079 standards.

- Test with a notified body such as TÜV Rheinland, DEKRA, or SGS Baseefa.

- Obtain EU-Type Examination Certificate and maintain compliance records for at least 10 years.

Conclusion – Know Your Zone

Hazardous area classification is not just a compliance exercise-it’s a life-saving strategy. By aligning operations with global standards like ATEX and IECEx, companies can safeguard personnel, protect assets, and maintain operational integrity. For high-risk zones like Zone 0, the use of certified intrinsically safe equipment is non-negotiable. As industries evolve, proactive compliance with these standards ensures not just safety, but also global trade readiness.

Leave a Reply