We live in a world surrounded by textiles- from the clothes we wear to the furnishings in our homes and workplaces. While these materials add comfort and functionality to our lives, they also pose a potential fire hazard. Understanding how fabrics respond to fire is paramount for safety, and a key metric in this understanding is the Limiting Oxygen Index (LOI).

Revisiting the Basics: What Exactly is LOI?

Limiting Oxygen Index (LOI) is the minimum concentration of oxygen in a mixture of oxygen and nitrogen that will just support the combustion of a material under specific test conditions. Think of it as the “oxygen threshold” for a material to burn.

- High LOI = High Flame Resistance: A material with a high LOI requires a greater percentage of oxygen in the atmosphere to sustain burning. Since normal air contains approximately 21% oxygen, any material with an LOI significantly above this value is considered self extinguishing or flame-resistant under typical atmospheric conditions.

- Low LOI = High Flammability: Conversely, materials with a low LOI can readily burn even in normal air, indicating higher flammability. In general, LOI less than 21% is considered as Low LOI.

How LOI is measured?

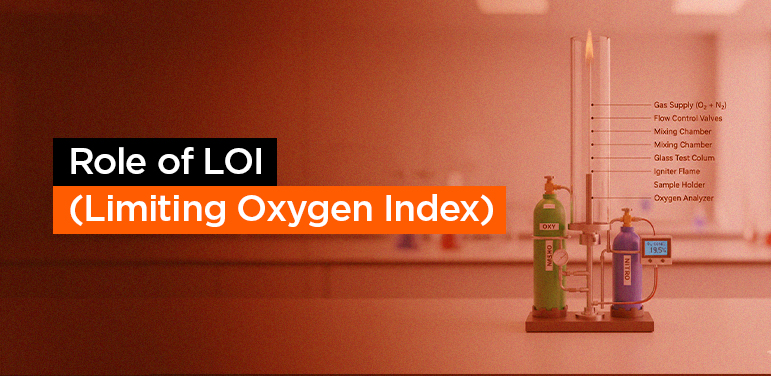

It is measured in a controlled laboratory environment using a standardized test method, typically ASTM D2863 or ISO 4589.

To measure the Limiting Oxygen Index, a vertical test apparatus is used, typically comprising a transparent glass column open at the top and bottom to allow a controlled flow of gases. The column is connected to a gas mixing system that precisely regulates the flow rates of oxygen and nitrogen. These gases are mixed in varying ratios to create an atmosphere with a known oxygen concentration inside the column.

A sample of the material to be tested-usually cut into a specific size and shape, such as a strip or rod-is mounted vertically inside the column using a suitable holder that does not interfere with combustion.

Once the sample is in place, a steady flow of the oxygen-nitrogen mixture is established from the bottom of the column upward. The top of the sample is then ignited using a small pilot flame. The observer monitors whether the material continues to burn on its own or extinguishes after the flame is removed.

- If the flame self-extinguishes, the oxygen concentration is increased slightly and the test is repeated.

- If the sample continues to burn, the oxygen level is reduced incrementally.

This process is repeated until the minimum concentration of oxygen that supports continuous combustion is found. This value is recorded as the Limiting Oxygen Index, expressed as a percentage.

The formula can be simplified as:

LOI (%) = [Oxygen] / ([Oxygen] + [Nitrogen]) × 100

This means that a fabric with a higher LOI requires a greater percentage of oxygen to keep burning. Since normal atmospheric air contains about 21% oxygen, materials with an LOI higher than 21% are self-extinguishing in air, making them naturally flame-resistant.

Why LOI Matters in Flame Resistance

It is a quantitative indicator of a material’s ignitability and flammability. Materials used in protective clothing (like firefighting gear or industrial FR wear) must not continue burning once the ignition source is removed. It helps manufacturers choose the right materials that are less likely to propagate flame.

For example:

Cotton has a Limiting Oxygen Index of approximately 18%, which means it ignites easily in normal air, as the atmosphere contains around 21% oxygen. Any material with an LOI below 21% is considered easily combustible.

In contrast, Modacrylic fibers have an LOI of around 30–34%, making them inherently flame-resistant and much safer in environments where fire risk is a concern.

And there are many more fibers in textile whose LOI is described below

| Fiber | LOI% | Fiber | LOI% |

|---|---|---|---|

| Cotton | 16-18 | FR Viscose | 28-32 |

| Rayon | 17-19 | m-Aramid | 28-30 |

| Polyester | 20-22 | p-Aramid | 28-30 |

| Nylon | 20-24 | Polyacrylate | 40-42 |

| Wool | 24-25 | PBI | 40-42 |

| Modacrylic | 30-34 | OPAN | 54-56 |

| PLA | 26-35 | PBO | 65-70 |

| Kermel | 30-32 | PVC | 40-42 |

LOI helps predict whether a material will continue to burn in ambient air. A higher LOI means greater flame resistance. In multi-layered protective clothing, fabrics are often blended for performance, comfort, and cost-effectiveness. It helps evaluate how the blend behaves in terms of flame resistance and guides the development of balanced, high-performance fabric systems.

Many flame-resistant clothing standards (NFPA 2112, EN ISO 11612, etc.) require a minimum level of flame resistance. This testing is often a preliminary screening tool to determine if a material is worth pursuing for more expensive and rigorous flame tests.

LOI – Not the Only Metric

While LOI is a valuable indicator, it’s not the sole determinant of fire safety. Other tests and factors include:

Vertical flame test (ASTM D6413)

Heat transmission performance (HTP)

Char length and after-flame time (NFPA2112)

A fabric with a higher rate may still fail other performance tests if it melts, drips, or doesn’t provide thermal insulation.

Conclusion

Limiting Oxygen Index plays a pivotal role in understanding and comparing the flame resistance of different fabrics. It offers a simple yet effective way to assess a material’s behavior in oxygen-rich environments, guiding manufacturers and safety professionals in choosing the right protective solutions.

While it should be used alongside other testing methods, it remains a foundational tool in the design, development, and certification of flame-resistant textiles.

Read more innovative articles here.

Leave a Reply