Flame-retardant (FR) fabrics are available in two categories:

- The treated FR where 100% cotton or cotton rich fabric is treated with phosphorus-based compounds to achieve fire resistance.

- The inherent FR, where the fibers are engineered to have a chemical composition which resists the propagation and sustenance of fire.

Several technologies are in existence for producing flame-retardant cotton fabrics, with one common treatment method being the application of tetrakis-(hydroxymethyl)-phosphonium chloride on the fabric surface, often referred to as THPC finish. This treatment is widely recognized for its ability to enhance the flame-retardant properties of both cotton and poly/cotton substrates. In this blog, our primary emphasis will center on exploring the world of flame-retardant cotton fabrics treated specifically with THPC finish.

But there is always a question about the durability of a treated FR fabric. Is there a loss of performance due to washing and how durable is the clothing in protecting the user from heat and flame hazard.

To address this concern a research study [House, J. R., & Squire, J. D. (2004). International Journal of Clothing Science and Technology, 16 (4), pp. 361-367] was conducted in the UK. The aim of the study was to assess the protection from a new THPC treated coverall as compared to a coverall which was worn and washed over a prolonged period.

The coveralls were worn for at least 12 hours per day for approximately 56 days over a 12-week period and had been washed approximately 20 times. Post usage both the used and unused coveralls were exposed to a manikin test to determine the body burn percentage.

In the testing process, the manikin was dressed in a used/washed coverall and exposed to flames for varying durations, specifically 2, 4, 6, 8, and 10 seconds. These trials were conducted again using new coveralls. The results were then assessed by measuring the potential severity of burn injuries, which were classified into three categories: first, second, and third-degree burns. These classifications correspond to the extent of skin damage observed during the testing. To clarify, first-degree burns involve surface reddening without blistering; second-degree burns affect multiple layers of the skin, resulting in blistering but no scarring; and third-degree burns penetrate through the skin, leading to scarring.

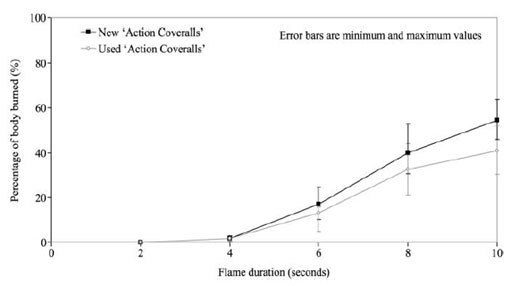

Figure 1. Mean body surface area with a predicted second or third degree burn when new and used coveralls were exposed to flame (Source: House, J. R., & Squire, J. D. (2004). International Journal of Clothing Science and Technology, 16 (4), pp. 361-367)

As can be seen from Fig. 1, both the used and new coverall provide good protection from burns from a flash fire. More importantly, the level of protection against burns afforded by worn and used coverall was at least as good as, or better, than when the coveralls were new.

It is likely that the used garments provided better protection due to physical changes to the materials during wear, as there is no known mechanism by which flame retardancy due to THPC might be improved chemically during laundering. When garments are worn the material layers and the fibers within rub-together which increases both the thickness of the layers and the air-trapped within them. The material layers are then described as having an increased “loft” which enhances protection against heat and flame.

The study also concluded that THPC treated cotton and cotton-rich FR clothing is suitable for protection from the expected risks of fire and flash exposure even after repeated wear and wash cycles.

As an example of similar behavior, one of our THPC treated cotton fabrics (350 GSM, from Tarasafe’s range of electric arc protection clothing) was found to display enhanced arc protection after repeated wash cycles. The fabric’s ATPV & ELIM values [measured as per IEC 61482-1-1:2019] increased from 14 cal/cm2 and 13 cal/cm2, respectively, after 5-washes to 19 cal/cm2 and 16 cal/cm2, respectively, after 50-washes. This observation confirms the finding of above study that multiple washes of THPC treated cotton FR clothing may not necessarily lead to reduced protection performance.

However it is very important to note that the protection level is maintained only if the garments are washed in accordance with the manufacturer’s recommendation. Exposure to and deposition of soap, petrol, oil and grease will reduce the protection level of any FR clothing made from treated cotton fabric or inherent flame-retardant fabrics.

Leave a Reply