“Necessity is the mother of invention.†The famous proverb befits the case of the evolution of Flame Resistant Protective clothing.

Protective clothing has been in existence since the time before Christ when the kingdoms and dynasties like Greeks and Persians had forged war. People wore mechanized garments which would stand tough and sturdy in difficult times. The same motives were documented by famous explorer and historian Marco Polo who described the clothing made by Mongolians as “fabric which would not burnâ€.

However, the advent and introduction of flame resistant protective clothing in the modern world took time until in 1600s, when there was a rising demand of flame resistant protective clothing in the Paris theaters because the cinema halls where susceptible to fire outbreaks. Clay and Plaster of Paris were used to coat normal shirts making them flame resistant. This progressed to clothes made of fabric coated with alum and ammonium in the 1800s.

It was the industrial revolution that truly triggered the momentum of flame resistant protective clothing and made way to the dawn of protective workwear. Whether it was the introduction of blast furnaces in 1709 or the discovery of short pulse electric arc in 1801, it was the sheer demand of safe and durable workwear for the everyday labourer that made the textile mills and garment manufacturers innovate and improvise on quality flame resistant protective clothing. Since then the world has seen a sea of development in flame resistant protective clothing.

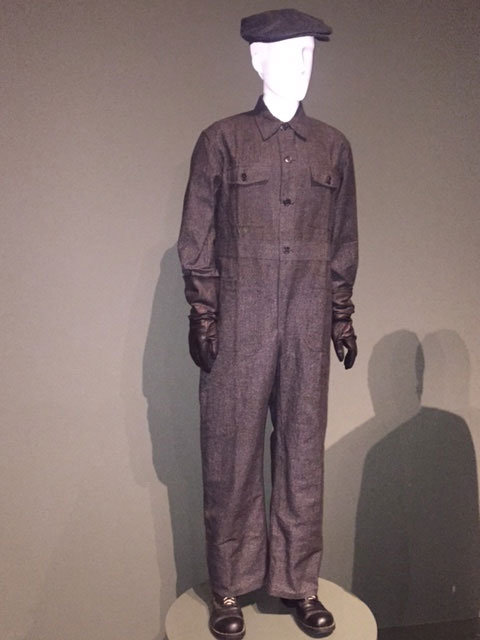

Following are some of the illustrations of workwear worn in the 1900s

The industry of flame resistant protective clothing became so vital to human life that legislations like the U.S. Flammable Fabrics Act 1953 were enacted and exercised. Subsequently, the 2000s again became a decade of defining flame resistant protective clothing more specifically and professionally.

There are various hazards that the worker needs to be protected from while working – Flash Fire, Electric Arc Flash, Molten Metal Splash, Hazardous Chemicals, Harsh Weather and Low Light conditions are some of the notable risks associated with industrial workers.

International Standards like NFPA 2112, NFPA 70E, ISO 11611:2007, ISO 11612:2008, EN 61482-1-1:2007, EN 61482-1-2:2007, ISO 15797:2002, EN 13034: 2005 and many others were drafted and are till date followed to create the flame resistant protective clothing for various risks and hazards.

The current protective clothing market is growing like never before. Even with the sluggish economic conditions in the west over the past decade, there has been notable growth in the personal protective clothing industry. According to a couple of web articles by Research & Markets and Grand View Research, the market is supposed to cross yearly revenue of USD 60 billion by 2024 compared to USD 38 billion in 2015. However, product innovation remains the key factor for the years to come. According to a web article by Frost & Sullivan, the industry will be a very different one. It states, “The competitive landscape for the PPE industry will be very different in 2030, driven by innovation, disruptive business models, and advent of smart and wearable PPE products transforming the workplace to a connected domain enhancing worker safety and productivityâ€.

We at Tarasafe have been in the business of protecting people in the fire hazardous industry for more than two decades. We believe in constant product innovation as per the market requirements. The need and necessity drives us to push ourselves to improvise and discover new products that protect the wearer from hazardous working conditions. Be it a range of protective clothing created to protect the wearer from Arc Flash or providing protection against the dangerous UV rays, Tarasafe has always thrived on product development and is always adaptive and proactive to industry demands.

Here are some of the examples of our work:

The essence of our newest developments is “lightweight comfort, heavyweight protectionâ€. The focus is on providing the lightest weight fabrics performing high level of protection. Our innovative design team incorporates garment features which lower heat stress and allow more breathability coupled with better ergonomics, leading to all-round comfort for the wearer.

Very good blogs. Are you an American company?

Thank you for your appreciation. We are an Indian company and specialise in Flame Retardant Workwear. We manufacture and export Flame Retardant clothing.

Could you tell me what is the certification requirements of arc flash suit? Which regulatory body approve the company for manufacturing arc flash suit? Do you meet all the internal requirements NFPA &0 and ASTM standards?